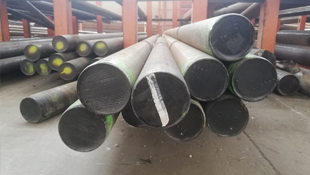

Asıl 4140 Steel Between 20-220 Dıameters

WHAT IS BREEDING STEEL?

Reclamation steels are unalloyed and alloyed machine-building steels that are suitable for hardening, especially in terms of carbon content, and show high toughness at a certain tensile strength at the end of the curing process.

The curing process is defined as the whole of first hardening and then spiritualization processes, in which the steel part will eventually be given high toughness. Due to the superior mechanical properties gained at the end of the treatment process, curing steels are used in the manufacture of parts such as various machine and engine parts, forged parts, various bolts, nuts and deflections, crankshafts, axles, control and drive parts, piston rods, various shafts and gears. are used in a wide area. For this reason, after construction and non-alloy steels, reclamation steels are the type of steel produced and used at the highest rate.

The selection of the appropriate breeding steel and the application of the correct breeding process require a lot of attention and experience. The good results of the reclamation process (reaching the desired toughness or hardness value) are closely related to the internal structure cleaning of the steel used. Internal structure cleaning is the process of purifying the liquid steel from gases (hydrogen, oxygen and nitrogen) in the molten state and cleaning it from oxide, sulfur inclusions.

BREEDING PROCESS

The reformation process has been described as the process of hardening followed by spiritualization. In the following, the hardening and tempering processes for steels are generally described separately.

|

AISI/SAC |

DIN |

AFNOR |

BS |

|

4140 |

42CrMo4 |

42CD4 |

708M40 |

|

4340 |

36CrNiMo4 |

35NCD6 |

817M40 |

|

5140 |

41Cr4 |

42C4 |

530M40 |